document.addEventListener("DOMContentLoaded", function() {

let $awsForms = jQuery(".aws-container");

if ( $awsForms.length > 0 ) {

$awsForms.each(function( index ) {

if ( ! jQuery(this).closest("#wcfmmp-store").length > 0 && ! jQuery(this).closest("#wcfmmp-store-content").length > 0 ) {

jQuery(this).find('form').attr('action', 'https://avpay.aero/');

jQuery(this).data('tax', '');

}

});

}

});

if (typeof wcpt_persist_params === 'undefined') {

var wcpt_persist_params = [];

}

wcpt_persist_params.push('hide_form');

if (typeof wcpt_persist_params === 'undefined') { var wcpt_persist_params = []; } wcpt_persist_params = wcpt_persist_params.concat(["min_price","max_price","rating_filter","filter_aad-mode","filter_aad-pin-type","filter_aircraft-hire","filter_aircraft-size-mtow","filter_aircraft-type-1","filter_aircraft-type-2","filter_airs-hang-gliding","filter_airs-kite-taster","filter_airs-microlight-flights","filter_assisted-or-unassisted","filter_atlas-elastic-wrist-mount","filter_avpay-banners","filter_blackbushe-hour-building","filter_bright-creativity-1","filter_cfs-hour-building-options","filter_cfs-package-type","filter_cloud-dancer-spec","filter_clouddancer-canopy-type","filter_colour","filter_darl-landing-fees","filter_delivery-seht","filter_donations","filter_duration","filter_ecgb-gyro-membership","filter_egcb-north-west-gyro","filter_egcb-north-west-gyro-book","filter_egcb-north-west-gyro-eq","filter_egcb-north-west-gyro-gift","filter_egcb-north-west-gyro-hrs","filter_egcb-north-west-gyro-select","filter_egcb-north-west-gyro-train","filter_egcb-north-west-gyro-trial","filter_egnc-cumbria-mic","filter_egnc-de-ice","filter_egnc-de-ice-call-out","filter_egnc-fuel","filter_egnc-handling-fees","filter_egnc-security-charges","filter_egne-retford-airport-class","filter_egne-tas-training","filter_egnh-hangar-3-ac-s","filter_egnh-hangar-3-c","filter_egnh-hangar-3-h","filter_egnh-hangar-3-hours","filter_egnh-hangar-3-ooh","filter_egnh-hangar-3-p","filter_egnh-hangar-3-s","filter_egnh-hangar-3-stocks","filter_egnh-helispeed-academy-e","filter_egnh-helispeed-academy-f","filter_egnh-helispeed-academy-l","filter_egnh-helispeed-academy-t","filter_egpg-hangarage","filter_egpg-landing-fee-fixed-wing","filter_egpg-landing-fee-heli","filter_egpg-main-hangar","filter_egpg-oil-hyd-fluid","filter_egpg-parking-fees-size","filter_egpg-parking-fees-time","filter_email-broadcast-list","filter_enstone-circuit-fees","filter_execujet-parking","filter_execujet-weights","filter_flightline-aviation-deposit","filter_fuel","filter_fwma-airport-parking","filter_gender","filter_gyro-ground-school","filter_hangarage-size","filter_heli-charter","filter_heli-strato-sunglasses","filter_heli-tropo-sun-glasses","filter_heliair-faa","filter_heliair-helicopter-list","filter_heliair-pilot-serv","filter_heliair-test-fees","filter_heliair-trial","filter_helicopter-type","filter_hobbs-datcon","filter_hwel-tour","filter_involvement-in-aviation","filter_landing-fee","filter_landing-fees-tonnes","filter_lszh-execujet-zurich-conf","filter_lszh-execujet-zurich-gpu","filter_lszh-execujet-zurich-oil","filter_lszh-execujet-zurich-park","filter_lszh-execujet-zurich-tow","filter_lszh-execujet-zurich-tran","filter_mtow","filter_multiflight-24-hour-parking","filter_multiflight-handing-mtow","filter_multiflight-handling-fuel","filter_multiflight-landing-fee","filter_nemy-oil1","filter_nemy-oil2","filter_nemy-oil3","filter_number-of-people","filter_out-of-hours-times","filter_package","filter_plane-size","filter_porterage","filter_price","filter_private-flyer-days","filter_select-aircraft-page","filter_select-banner-type","filter_select-day","filter_select-directory","filter_select-hours","filter_select-number-of-passengers","filter_select-term","filter_size","filter_special-badge","filter_strathaven-airfield-fly","filter_strathaven-airfield-hang","filter_strathaven-airfield-landing","filter_strathaven-airfield-mi","filter_strathaven-airfield-out","filter_stunden-wahlen","filter_uk-01-tours","filter_uk-10-r44-block-rates","filter_uk02-tours","filter_uk03-instructor","filter_uk10","filter_uk10-ac-landing","filter_uk10-ground-school","filter_uk10-hours","filter_uk10-landing-circuits","filter_uk10-pilot-services","filter_uk10-shop","filter_uk10-test-fees","filter_uk11","filter_uk11-crew-lounge","filter_uk11-days","filter_uk11-fees","filter_uk11-helipad-transfer","filter_uk11-keys","filter_uk11-parking","filter_uk11-parking-car","filter_uk11-passenger-waiting","filter_uk11-vip-lounge","filter_uk11-working-hours","filter_uk12-bespoke-tours","filter_uk12-pleasure-flights","filter_uk12-pplh-training","filter_uk12-self-hire","filter_uk12-trial-lessons","filter_uk12-type-rating","filter_uk19-flight-academy-dist","filter_uk19-flight-academy-time","filter_uk20-micro-valets","filter_uk20-micro-valets-gold","filter_uk20-micro-valets-silver","filter_uk22-t6-harvard-exp","filter_uk24-aps-promotions-fb","filter_uk24-aps-promotions-fl","filter_uk24-aps-promotions-pm","filter_uk25-dorset-gliding-club-f","filter_uk25-dorset-gliding-club-i","filter_uk25-dorset-gliding-club-l","filter_uk25-dorset-gliding-club-s","filter_uk25-dorset-gliding-landing","filter_valet"]);

https://avpay.aero/wp-content/plugins/complianz-gdpr-premium/pro/tcf-stub/build/index.js

var breeze_prefetch = {"local_url":"https:\/\/avpay.aero","ignore_remote_prefetch":"1","ignore_list":["\/cart-2\/","\/checkout\/","\/my-account\/","\/cart-2\/","\/checkout\/","\/wp-admin\/"]};

https://avpay.aero/wp-content/plugins/breeze/assets/js/js-front-end/breeze-prefetch-links.min.js

https://avpay.aero/wp-includes/js/jquery/jquery.min.js

https://avpay.aero/wp-includes/js/jquery/jquery-migrate.min.js

https://avpay.aero/wp-includes/js/underscore.min.js

var _wpUtilSettings = {"ajax":{"url":"\/wp-admin\/admin-ajax.php"}};

https://avpay.aero/wp-includes/js/wp-util.min.js

var wc_add_to_cart_params = {"ajax_url":"\/wp-admin\/admin-ajax.php","wc_ajax_url":"\/?wc-ajax=%%endpoint%%","i18n_view_cart":"View cart","cart_url":"https:\/\/avpay.aero\/cart-2\/","is_cart":"","cart_redirect_after_add":"no"};

https://avpay.aero/wp-content/plugins/woocommerce/assets/js/frontend/add-to-cart.min.js

var wc_add_to_cart_variation_params = {"wc_ajax_url":"\/?wc-ajax=%%endpoint%%","i18n_no_matching_variations_text":"Sorry, no products matched your selection. Please choose a different combination.","i18n_make_a_selection_text":"Please select some product options before adding this product to your cart.","i18n_unavailable_text":"Sorry, this product is unavailable. Please choose a different combination."};

https://avpay.aero/wp-content/plugins/woocommerce/assets/js/frontend/add-to-cart-variation.min.js

https://avpay.aero/wp-content/plugins/woocommerce/assets/js/jquery-blockui/jquery.blockUI.min.js

https://avpay.aero/wp-content/plugins/woocommerce/assets/js/js-cookie/js.cookie.min.js

var woocommerce_params = {"ajax_url":"\/wp-admin\/admin-ajax.php","wc_ajax_url":"\/?wc-ajax=%%endpoint%%"};

https://avpay.aero/wp-content/plugins/woocommerce/assets/js/frontend/woocommerce.min.js

var cmplz_tcf = {"cmp_url":"https:\/\/avpay.aero\/wp-content\/uploads\/complianz\/","retention_string":"Retention in days","undeclared_string":"Not declared","isServiceSpecific":"1","excludedVendors":{"15":15,"46":46,"56":56,"66":66,"110":110,"119":119,"139":139,"141":141,"174":174,"192":192,"261":261,"262":262,"359":359,"375":375,"377":377,"387":387,"415":415,"427":427,"431":431,"435":435,"458":458,"462":462,"482":482,"508":508,"512":512,"521":521,"527":527,"528":528,"531":531,"544":544,"569":569,"581":581,"587":587,"626":626,"644":644,"667":667,"711":711,"713":713,"733":733,"734":734,"736":736,"748":748,"756":756,"776":776,"786":786,"806":806,"809":809,"822":822,"836":836,"856":856,"870":870,"873":873,"876":876,"879":879,"882":882,"888":888,"890":890,"894":894,"899":899,"908":908,"909":909,"923":923,"970":970,"975":975,"986":986,"988":988,"996":996,"1011":1011,"1015":1015,"1018":1018,"1022":1022,"1039":1039,"1044":1044,"1051":1051,"1075":1075,"1078":1078,"1079":1079,"1087":1087,"1094":1094,"1102":1102,"1107":1107,"1114":1114,"1115":1115,"1121":1121,"1123":1123,"1124":1124,"1139":1139,"1141":1141,"1149":1149,"1156":1156,"1164":1164,"1167":1167,"1173":1173,"1181":1181,"901":901,"1198":1198,"1199":1199,"1211":1211,"1216":1216},"purposes":[1,2,3,4,5,6,7,8,9,10,11,1],"specialPurposes":[1,2],"features":[1,2,3],"specialFeatures":[1,2],"publisherCountryCode":"GB","lspact":"N","ccpa_applies":"","ac_mode":"1","debug":"","prefix":"cmplz_"};

https://avpay.aero/wp-content/plugins/complianz-gdpr-premium/pro/tcf/build/index.js

var wcfm_maps = {"lib":"google","map_type":"roadmap"};

var fix_cart_fragments_params = {"currency_symbol":"pound;","do_run":"yes"};

https://avpay.aero/wp-content/plugins/currency-per-product-for-woocommerce-pro/assets/js/fix_cart_fragments.js

var bb_powerpack = {

search_term: '',

version: '2.36.2',

getAjaxUrl: function() { return atob( 'aHR0cHM6Ly9hdnBheS5hZXJvL3dwLWFkbWluL2FkbWluLWFqYXgucGhw' ); },

callback: function() {}

};

var woopack_config = {"ajaxurl":"https:\/\/avpay.aero\/wp-admin\/admin-ajax.php","page":0,"current_page":"https:\/\/avpay.aero\/company\/uk21-micro-maintenance\/","woo_url":"https:\/\/avpay.aero\/wp-content\/plugins\/woocommerce\/"};

( function() {

window.onpageshow = function( event ) {

// Defined window.wpforms means that a form exists on a page.

// If so and back/forward button has been clicked,

// force reload a page to prevent the submit button state stuck.

if ( typeof window.wpforms !== 'undefined' && event.persisted ) {

window.location.reload();

}

};

}() );

Skip to content

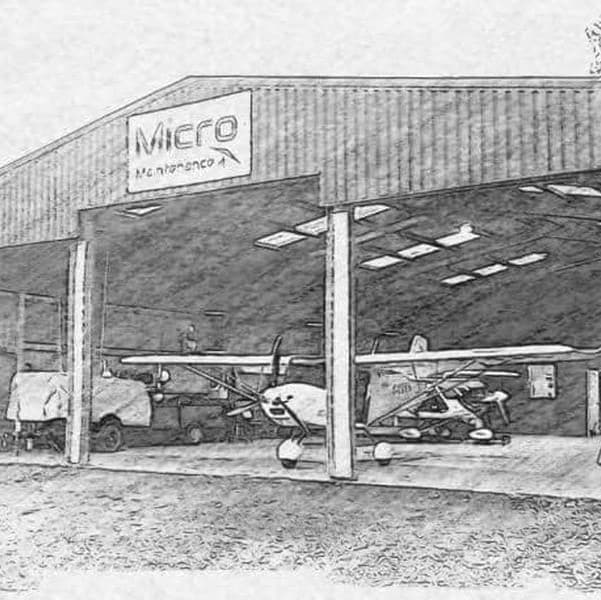

Micro Maintenance is the number one maintenance, service and inspection centre for Microlight and Sports Light Aircraft, in the Midlands! We offer the complete aircraft owner’s package be it Permit to Fly Inspections, crash repairs, scheduled engine or airframe maintenance or full customisation of your aircraft.

Our team comprises of BMAA & LAA Inspectors, three Rotax Engineers, two stroke Specialist, Avionics Engineers and Airframe Mechanics.

We also carry a huge range of consumable aircraft parts for most mainstream machines.

Micro Maintenance is your one stop shop for all things Sports Aviation.

Showing all 11 results

Showing 1 – 11 of 11 results Showing all 11 results Showing the single result No results found

Filters Sort results Reset Apply

Micro Maintenance offering full engine and airframe service, maintenance and repairs to the microlight community. Our team comprises of Rotax Engineers, Aircraft Inspectors, Test Pilots and Instructors to offer you the best service for your Aircraft.

Micro Maintenance have approved Rotax Engineers fully qualified to service and maintain your Rotax engines. Our 2 and 4 Stroke specialists can also offer a fault finding service to diagnose any issues that you may have with your engine.

Micro Maintenance is complemented by two BMAA Inspectors able to perform all inspection work required for your Microlight aircraft.

All two seat Microlight aircraft are subject to airworthiness regulations which ensure that each design is approved as airworthy. Each of these aircraft is awarded a Permit to Fly by the UK Civil Aviation Authority. The Permit is validated each year by having an inspection and check flight. The inspection is carried out by an Inspector authorised by the BMAA. The owner may carry out their own check flight.

Modification Inspections

If an owner wishes to modify the design of his aircraft, this might be by adding a fuel tank, changing the suspension or simply installing a radio, the regulations require that the modification is approved to ensure that it does not compromise the airworthiness of the design. The BMAA Technical Office is able to make the assessment of a modification for BMAA members.

Weight Reports

Micro Maintenance uses calibrated scales to accurately weigh your aircraft to submit a detailed weight and balance report required for your PTF. At time of application your aircraft must have a valid weight report. The primary purpose of the BMAA’s weight and balance policy is to ensure that the empty weight and balance of every BMAA aircraft is sufficiently accurately known to allow pilots to load their aircraft safely.

Micro Maintenance offer an airframe scheduled maintenance service, following the manufacturers annual/150hr (C service) inspection and maintenance worksheet we can undertake all work required and provide you with a detailed report for your paperwork and piece of mind.

All works are undertaken by our experienced Mechanics and Inspectors ensuring all work is carried out to the highest standards.

Micro Maintenance is a recognised maintenance facility based at Darley Moor Airfield. Our experienced team of Inspectors, Rotax Engineers and airframe Mechanics are able to carry out all repairs to your aircraft be it a minor repair or a major rebuild.

Airframe Repairs

Working with you we are able to accurately quote any repair and get you back in the air in the quickest possible time. Micro Maintenance have experienced work on all major manufacturers of Microlight aircraft and supply only genuine parts for your repair.

Accident Repairs

Should the worst happen, our professional team can resolve your incident from collection to completion. We can recover your aircraft from most UK locations to our purpose built accident repair centre based at Darley Moor Airfield, Derbyshire. Issue detailed accident reports and quotes for your insurance company, fully carry out all repairs, inspections, even return the aircraft to your home airfield.

Throughout this process our dedicated team will liaise with you, your insurance company and the BMAA to ensure the quickest turn around and return to the air.

Copyright © 2024 AvPay.aero All Rights Reserved.

To provide the best experiences, we and our partners use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us and our partners to process personal data such as browsing behavior or unique IDs on this site and show (non-) personalized ads. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Click below to consent to the above or make granular choices. Your choices will be applied to this site only. You can change your settings at any time, including withdrawing your consent, by using the toggles on the Cookie Policy, or by clicking on the manage consent button at the bottom of the screen.

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.

The technical storage or access that is used exclusively for statistical purposes. The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.

Manage consent Manage consent

Click outside to hide the comparison bar

Scroll To Top

(adsbygoogle = window.adsbygoogle || []).push({});